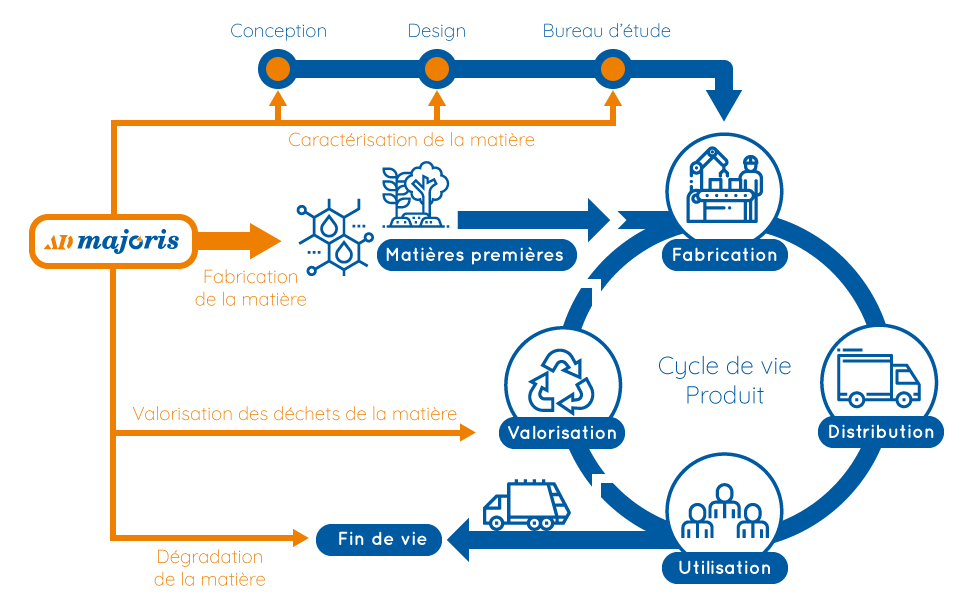

Expert knowledge of compound materials

AD majoris offers their expert knowledge from product design to manufacturing. Waste recycling is also an integral part of our approach.

Innovation and design

In collaboration with their customers, suppliers, university partners and through their participation in several collaborative projects, AD majoris has acquired expert knowledge that enables them to offer products or design advice that integrates the new demands and market trends, their work allowing them to offer:

- a wide selection of natural fibers and by-products from the wood industry and their synergy in polymers

- the use of a range of bio-based polymers which require less conversion energy while reducing the use of materials coming from fossil resources.

- ADmajoris provides customers with a databank including all their internal and external resources in terms of research and development (fundamental research or direct application) and all their various technical documentation.

- This databank also includes a whole series of recipes available concerning specific effects, such as resistance to scratching, soft touch, while adapting their experience to your needs.

Research projects

In collaboration with customers and suppliers. As an active member of Plastipolis and Axelera competitiveness centres, AD majoris participates in several collaborative projects.

AD majoris and their main directions R & D in Eco-Design:

- Substitution of speciality polymers

(PA, PC, PBT) with materials such as polypropylene reinforced with long glass fibers (new AD majoris technology). - Wide selection of natural fibers

For incorporation into polymers. - Use of bio-based polymers,

whether with or without natural fibers, which require less conversion energy while reducing the use of materials coming from fossil resources. - Synergies of nano-components in the thermoplastic matrices (fire resistance, electrical and thermal conductivity, traceability, recycling, etc.).

Recycling of raw materials

AD majoris has a wide experience in this field and makes their know-how available to their customers.

Their goal: to help their customers to treat different speciality polymer wastes, coming from industrial parts.

Such materials can be recycled using additives depending upon their future applications, thus becoming part of an overall environmental approach.

An eco-friendly action: a good citizen gesture.

Production and technology

Management on SAP system and statistical process control.

Production

AD majoris has two production units with twin-screw extrusion lines, one for producing polyolefin-based compounds and the other speciality polymer-based compounds. These lines are exclusively dedicated to long fibre thermoplastic materials (AD majoris technology).

The units are equipped with rigorous management and checks at each production step, providing the best quality for each of our products.

Logistics management

Making our customers’ wishes come true, quantifying their needs,

getting as close as possible to their expressed desires. The design of an on-line matrix proves to be a useful interface for achieving these goals!

For more efficiency, sharing and listening, establishing an exchange of electronic data with our customers and logistics partners, aiming to enhance the quality and flexibility of our information streams.

Fleet of machines consisting of 10 extruder lines

- Co-rotating twin-screw extruders with diameters from 21 to 90mm

- Specific extrusion lines dedicated to the technology developed by AD majoris for producing long fibre filled polymers

- The whole fleet of extruder lines is equipped with gravimetric feeders for a higher dosing efficiency for the various fillers and additives to be incorporated into the different polymers, as required by the applications.

- This fleet provides great flexibility for the volume of orders and AD majoris makes it available for their speciality products customers, from 25 kg to the 20-tonne full batch.

- Micronisation line for producing products in powder form

Packaging and logistics

The flexibility for order sizes ranges from 25 kg to a full lorry, along with various packaging systems (bag, big bag, cardboard container, tank, etc.).